Introduction

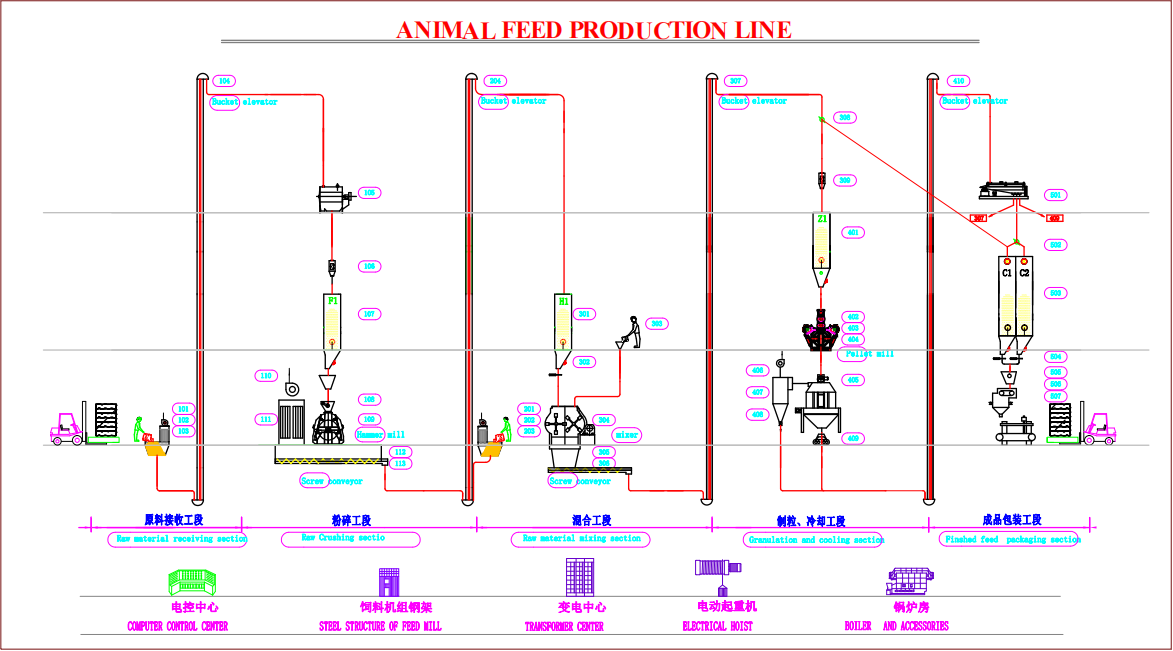

The 10-ton pig feed production line is a complete, automated system designed to produce high-quality pig feed pellets efficiently and consistently. Suitable for medium to large-scale feed mills, this line integrates advanced crushing, mixing, pelleting, cooling, and packaging technologies to ensure optimal nutrition, digestibility, and feed safety for swine at all growth stages (starter, grower, finisher, and sow feed).

Key Features:

- High Capacity – it can meet demands for commercial or integrated farming operations.

- Precision Formulation – Automatic batching system with computerized control for accurate ingredient proportions.

- Superior Pellet Quality – Equipped with the ring die pellet mill with the conditioner for durable, low-fines pellets with high starch gelatinization.

- Energy Efficiency – Optimized processes reduce power consumption (e.g., efficient hammer mill, air-cooling system).

- Flexible Recipes – Adjustable for various pig feed types (mash, pellets, or crumbles) with optional extruder for specialized feeds.

- Hygienic Design – Stainless steel contact parts and dust removal systems meet feed safety standards (e.g., ISO, FDA)