Introduction

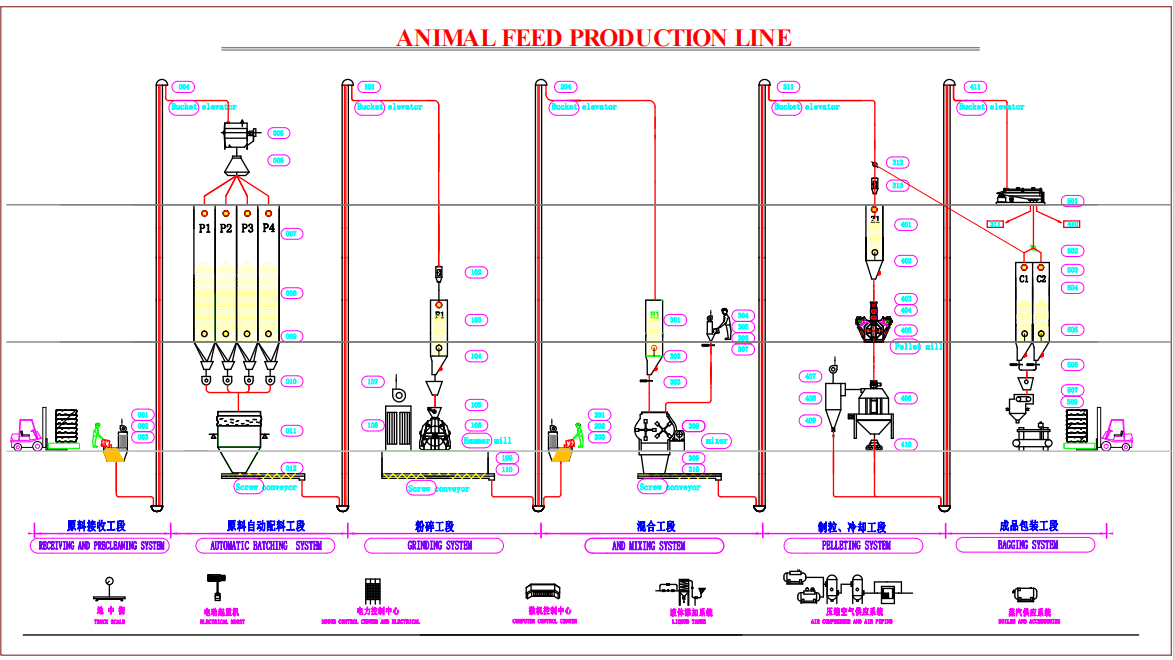

This is 5t/h cattle/ cows feed production line is designed for high-efficiency manufacturing of nutritionally balanced pellet or mash feed for dairy cows, beef cattle, and calves. The system integrates automation, energy efficiency, and precision processing to ensure consistent feed quality while reducing operational costs.

Key Advantages**

✅ High Efficiency & Automation

- Automated batching & mixing (PLC-controlled) ensures ±0.1% ingredient accuracy, reducing human error.

- Continuous pelleting & cooling minimizes downtime, achieving 95%+ production uptime.

✅ Superior Feed Quality

- Steam conditioning (80-90°C) improves starch gelatinization, enhancing digestibility.

- PDI (Pellet Durability Index) ≥95%, reducing fines and waste during transport.

- Customizable pellet size (Φ4-8mm) for different cattle growth stages.

✅ Energy & Cost Savings

- Low power consumption (80-120 kWh/ton) due to optimized motor efficiency.

- Heat recovery system (optional) recycles waste heat from cooling, cutting energy costs.

- Minimal feed loss (<0.5%) via closed-loop dust collection.

✅ Flexibility & Scalability

- Switchable between pellets & mash feed with minor adjustments.

- Expandable for additives (molasses, fats, probiotics) via liquid coating systems.

- Modular design allows future capacity upgrades (e.g., 10 T/H).

✅ Durability & Ease of Maintenance

- Heavy-duty alloy steel ring dies (lifespan ≥1,000 tons) reduce replacement frequency.

- Quick-release parts (e.g., hammer mill screens) enable fast cleaning & maintenance.

✅ Eco-Friendly & Safe

- Dust emission ≤20 mg/m³ (meets EU & EPA standards).

- Explosion-proof motors & spark detection for safe grain dust handling.