Introduction

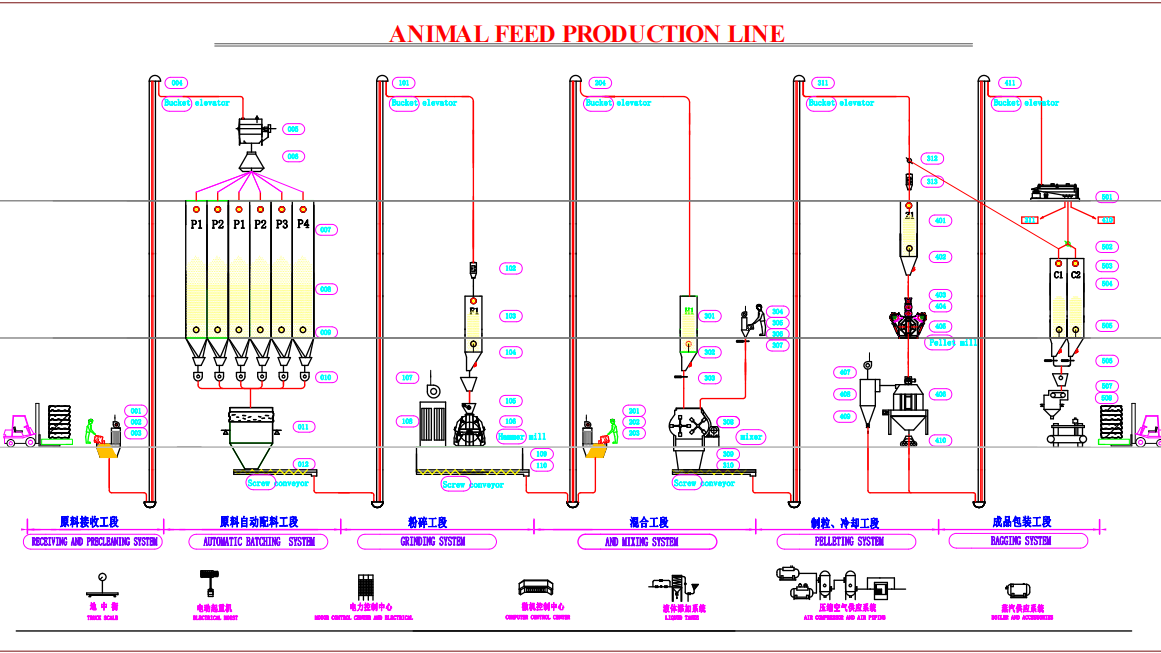

The 15t/hour chicken feed production line is a high-efficiency, automated system designed to produce nutritionally balanced poultry feed for broilers, layers, and breeders. Incorporating advanced grinding, mixing, pelleting, and cooling technologies, this line ensures consistent quality, optimal digestibility, and superior feed conversion ratios (FCR) to maximize poultry growth and egg production.

Key Features:

Hygiene & Safety – Stainless steel mixers, dust collectors, and optional post-pelleting liquid coating (enzymes/oils).

High Output – 15-ton/hour capacity, ideal for large-scale feed mills or integrated poultry farms.

Precision Nutrition – Automated batching system (±0.1% accuracy) with micro-ingredient dosing for precise formula control.

Pellet Durability – Conditioning + ring die pellet mill (3–8mm die options) produces low-fines, heat-treated pellets for improved FCR.

Flexible Formulas – Supports mash, pellets, or crumbles (optional crumbler for starter feeds).

Energy Saving – Optimized hammer mill (screen ≤1.5mm for chicks, ≤3mm for growers) and efficient air-cooling system.